clamp on ultrasonic flow meter installation guidelines

The TUF336 is an ultrasonic permanent fixed clamp-on flow metering solution for measuring flow rate and total flow with a volume pulse output and optional Modbus or 4-20mA flow proportional output which can be used as a stand alone meter or as part of an integral management system. The device can be mounted to a variety of materials including stainless steel iron copper PVC and resin.

Clamp On Ultrasonic Gas Flow Meters

Taking Clamp-on Ultrasonic flow measurement to a new level of performance.

. KEYENCEs FD-R Series Clamp-on Flow Meter is designed for pipes as large as 8. For reference our Dynasonics TFX-5000 ultrasonic clamp-on flow meter measures flow ranges from 00733000 gallons per minute with up to 05 accuracy. REFLECT MOUNT DIRECT MOUNT.

The New U1000MKII-HM is a Best Value Clamp-on Ultrasonic heat meter alternative to traditional inline energy meters for energy management and billing applications in domestic and commercial district or shared heating or cooling systems. The OPTISONIC 6300 is an ultrasonic clamp-on flowmeter for permanent mount installation. Martin Dingman of Siemens Industry Inc.

For successful ultrasonic flow meter installation locate the flow meter in a sheltered position away from falling water. The Tek-Clamp 1200A operates according to the difference in the Transit Time of Flight measured and determines the flow. It is a measurement system which is both easy to install and use.

The grease is used to eliminate any gaps between the transducer and the pipe wall. Ultrasonic clamp-on meter accuracy will vary depending on the brand and model. Discusses the new FS230 clamp-on ultrasonic meters for liquid and gases.

Ultrasonic Flow Meters HOW IS THE FLOW METER INSTALLED. Ideally flexible tubes should be used. The meter is housed in an aluminum enclosure with silicone.

User-Friendly Operating System Built-in keypad and simple menu system for fast and easy programming of pipe diameter pipe material liquid type and measurement units. The first step in the installation process is to select an optimal location for. C-PT Installation Guide 1 1 Introduction The C-PT ultrasonic flow transducer is used exclusively with the Panametrics line of ultrasonic flowmeters.

TEK-CLAMP 1200A SERIES ULTRASONIC CLAMP ON FLOW METER. Want to know more about ultrasonic clamp-on meters or have a. In later parts we will be discussing installation effects.

Typical MINIMUM straight pipe requirements are. Ideal for clean liquid applications this transit-time measurement technology reduces installation downtime and provides significant cost effectiveness when compared to inline flow measurement equipment especially in larger pipe sizes. Simple to install connect power and enter the pipe inside diameter.

User interface data for both meters are shown on the laptop screen. Both flow and temperature monitoring is possible for a wide variety of liquidsfrom water including pure. These transducers measure the flow rate of sonically-conductive liquids through pipes having diameters between.

Compare Siemens Clamp-On to Sick USM A series of meters of various types were investigated and Figure VI. It is particularly suitable for flow measurement of non-conductive liquids at any location where inline measurement is not possible or desirable. Topics covered are theory of operation new innovative features and benefits industry specific applications installation tips and tricks and selection criteria.

Flow Measurement SITRANS FS ultrasonic Clamp-on ultrasonic flowmeters SITRANS FSS200 ultrasonic flow sensor 3 Function Operating Principle The SITRANS FS system is a transit-time ultrasonic meter that provides exceptional performance using a non-intrusive clamp-on approach. If enough grease is not applied or the transducers are not clamped to the wall tightly the precision of measurement may be effected. Up to 15 cash back Clamp-on Ultrasonic Flow is a non-intrusive technology that is applied to the outside of process piping.

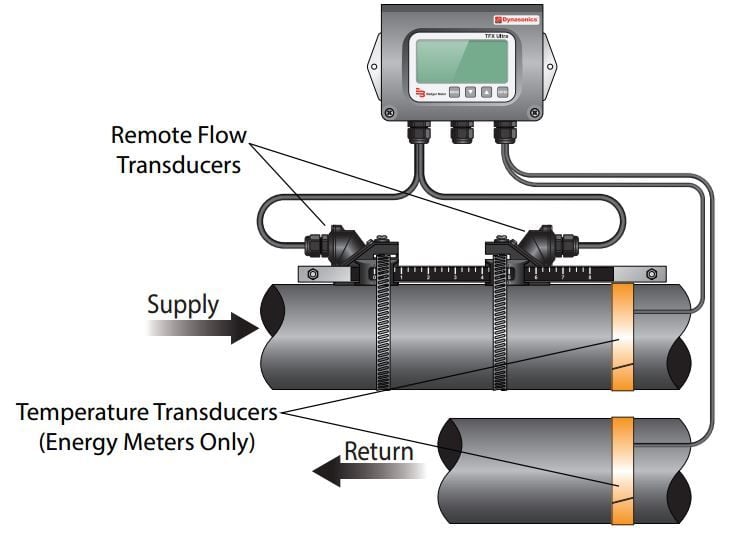

Tek-Clamp 1200A Ultrasonic Clamp On Flow Meter is designed to measure the fluid velocity of liquid in a full or closed pipe. U1000 Fixed Clamp-on Flow Meter - Hoskin Scientific Ltd. Non-Contacting Flow Measurement Ultrasonic transducers clamp on the outside of pipes allowing for installation without system shutdown and produces no pressure drop.

Apply a sufficient amount of grease at the installation area and clamp the transducers tightly on the pipe. 12 TYPICAL FP-4400 FLOW METER INSTALLATION The FP-4400 Portable Clamp-on Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe. It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications.

During ultrasonic flow meter installation care must be taken to ensure that the end fittings on the meter are not stressed during use. Measurement parameters of a wetted Sick ultrasonic meter and a Siemens Clamp-On ultrasonic meter are compared in Figure V. Minimum measuring range.

It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications. 5 How Accurate Are Ultrasonic Clamp-on Meters. Ultrasonic sensors transmit and receive acoustic.

The sensors are fixed to the pipe using metal chains straps or mounting rails. As the ultrasonic sensors are simply clamped on the pipe surface Katronic ultrasonic flow meters can be installed without the need to break into pipelines. Ideally the meter should be installed with straight lengths of tube either side for a.

Steps to the installation of the transducers. 03 to 12ms 30 ms for high precision sensors Pipe must be completely full within the sensor installation volume for accurate flow measurement All flowmeters assume a full pipe. General Installation Guidelines for TT Liquids Flowmeter.

12 TYPICAL F-4300 FLOW METER INSTALLATION The F-4300 Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe. The flowmeter consists of a stainless steel sensor rail with two integrated transducers or for large pipe. Locate an optimal position where the straight pipe length is.

Installation is easy and requires only a screwdriver. Ultrasonic flow meter installation guidelines Transducer Mounting Allocation. In the first of our application notes for ultrasonic clamp on meters it is astoundingly clear that the user has an important role in the setup of the clamp on meter but overrulingly the manufacturer meter quality plays a significant part in attaining accurate flow measurement results.

China Customized Clamp On Ultrasonic Flow Meter For Arduino Suppliers And Factory Wholesale Low Price Clamp On Ultrasonic Flow Meter For Arduino Gallop Technology

6000 Series Portable Ultrasonic Flow Meter

China Handheld Ultrasonic Flow Meter Clamp On China Handheld Ultrasonic Flow Meter Ultrasonic Flow Meter

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

Clamp On Ultrasonic Flow Meter Xtsensors

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

Flow Meter Ultrasonic Clamp On Flowma Wuf300 Cf

Si 3403 Clamp On Ultrasonic Flow Meter Sino Inst

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

Clamp On Ultrasonic Flow Meters Installation Guidelines Rms Engineering

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

Portable Clamp On Ultrasonic Flow Meter Rental Panametrics Pt878

Portable Ultrasonic Flow Meter Installation Tutorial How To Solve No Signal Message Youtube

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

The Technology Of Ultrasonic Flowmeter Wiratama Mitra Abadi Industrial Equipment

Tuf Clamp On Ultrasonic Flow Meter Apure

Clamp On Ultrasonic Flow Meters Installation Guidelines Rms Engineering